Are you wondering if our structure design is sustainable? Well, we asked our R&D engineer intern Anousha Masson to share her research and life cycle analysis on our most popular product, the FasTival.

Anousha, could you tell us how a product is sustainable?

To have a sustainable product, several parameters must be considered: the number of components, the type of materials/processes, the transport, the number of uses, the end of life of the product, etc.

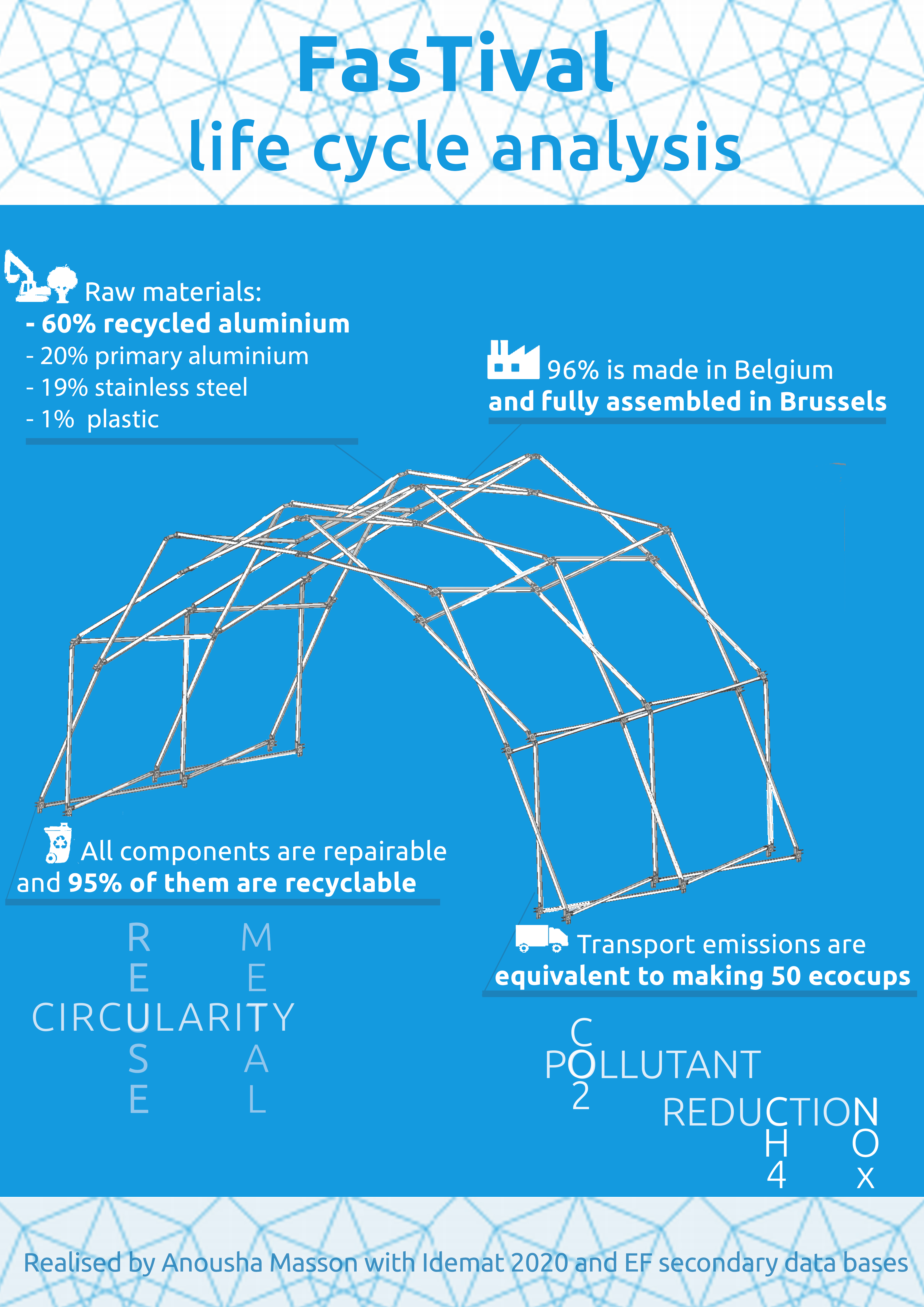

In a FasTival, there are 6 main families of components: aluminium profiles, aluminium joints, steel feet plate, Dyneema¹ cables and various fastening and assembly elements made of steel, aluminium, or plastic. The total weight of the components is 132 kg. Having light components and minimising the different types of components already helps to reduce the environmental impact of the product’s life cycle. These first elements are already good practices to obtain a sustainable product, but an in-depth study with the aforementioned parameters must be conducted. This is where numerical methods such as LCA come in.

What is a life cycle assessment (LCA)?

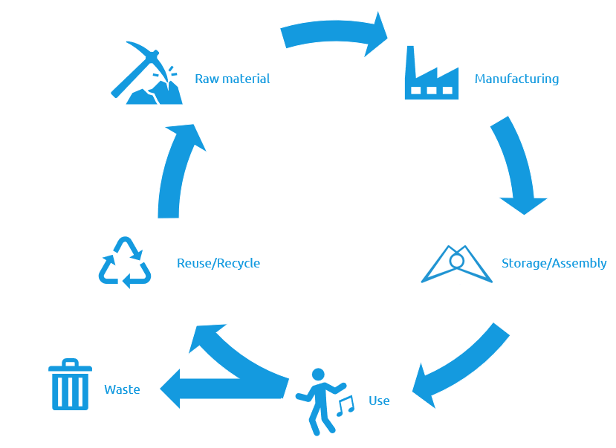

LCA is a tool used to identify, quantify, and evaluate the environmental impacts of a product, service, or activity. Indeed, all phases of the product’s cycle are assessed: from the time materials are extracted until the product end of life through the steps of manufacturing, transportation, storage, use, recovery, reuse, and disposal.

What is the first step in your study?

Before listing, quantifying, and filling in a database in Excel, it is necessary to define the purpose and scope of the study. Here, the study object is the FasTival pop up structure used for 1,000 days. The included steps are raw material extraction, manufacturing, assembly at Konligo, use, and end of life of the product with transport and packaging used between each step.

How did you find the information for each step?

To trace the life cycle of each component composing our event structure, I contacted our suppliers. For example, a scissor element is made of two beams, three plastic washers, two sleeve nuts and a stud bolt (fastener components). I have weighed and measured each component and I requested as much information as possible from the suppliers (material used, origin, forming process, type of packaging, type of transport…). The more precise the information, the more reliable and complete the analysis will be. This step was time-consuming, but it was crucial for obtaining successful results. Then, I completed an Excel database that converts the input data (weights, materials, processes, distances…) into output data (= environmental impacts).

Did you create this database or is there a universal method?

The databases used are Idemat 2020 developed at the University of Delft in the Netherlands, and EF secondary which comes from the European PEF project aimed at harmonizing LCA methods. In our study, we used the Idemat 2020 for raw materials and manufacturing steps. The EF secondary was used for transport, use and end of life phases. By using a universal method, I can compare the environmental impacts of a FasTival to other products.

What are the environmental impacts obtained?

The LCA gives us 5 results on environmental impact:

- an end-of-life score expressed millipoint (mPt), a unit common to all impact criteria (sum of damage to human health, ecosystems, and resources)

- a climate change score in kg CO2 equivalent, which combines the increase in the greenhouse effect, climate change, and the increase in the Earth’s average temperature

- a respiratory disease risk factor (= human health effects of potentially inhaled inorganic particle emissions)

- a result on water eutrophication in kg CO2 equivalent, considering the proliferation of aquatic vegetation, oxygen imbalance and the release of toxic substances by aerobic bacteria

- a result on the energy consumed in MJ (= total non-renewable primary energy consumed)

So, is the FasTival a sustainable product?

Yes, if it is used as many times as possible and recycled at the end of its life, it is indeed a sustainable product. So, it is also in the hands of our customers to make the most of the sustainable potential by taking good care of it. Secondly, since the most used material comes from recycling, the environmental impact is lower than for a FasTival produced with primary raw materials. And finally, durability is ensured through Belgian manufacturing and assembly (see image).

Did you know?

Using a FasTival for 1000 days has the same impact as producing and using 1050 disposable plastic cups.

¹ Lightweight material with tensile property comparable to steel cables