Frequently Asked Questions.

Are your questions not covered? We are only a button away.

General information

Why should I choose Konligo structures?

Konligo's innovative structures stand out due to the patented technology ensuring compactness for storage and transport, quick installation by two people, distinction in appearance and robustness with winds up to 100 km/h. Moreover, they are produced sustainably.

Which efforts does Konligo make towards sustainability?

Our commitment to sustainability is reflected in our operational processes:

- Production and assembly in Belgium, using suppliers as local as possible to minimize CO2 emissions.

- Adoption of a modular design to enhance interchangeability across our models, embodying eco-design principles.

- Collaboration with social enterprises to provide employment opportunities for those facing barriers to work due to disabilities.

- The used aluminium is 80% recycled.

Read more about our sustainable core values in this blog article.

Which types of events are Konligo structures best suited for?

Konligo structures are perfect for mobile stages, brand activations, pop-up booths, roadshows, product launches, press conferences, exhibition stands, and so on. The structures invite creativity and the possibilities are large. Get inspired here!

Product-specific

Which materials are used in the structures?

- 80% recycled aluminium for the frame, encompassing both the beams and the connective joints.

- The footplates are crafted from durable steel.

- The covers (membranes) are fabricated from high-quality polyester (240gr/m²) or PVC (510gr/m²), ensuring resilience and longevity.

- For wind bracing, we employ Vectran (kevlar) cables with XTR coating. Chosen for their superior strength and flexibility, it allows to maintain the structure's compactness without damaging the components.

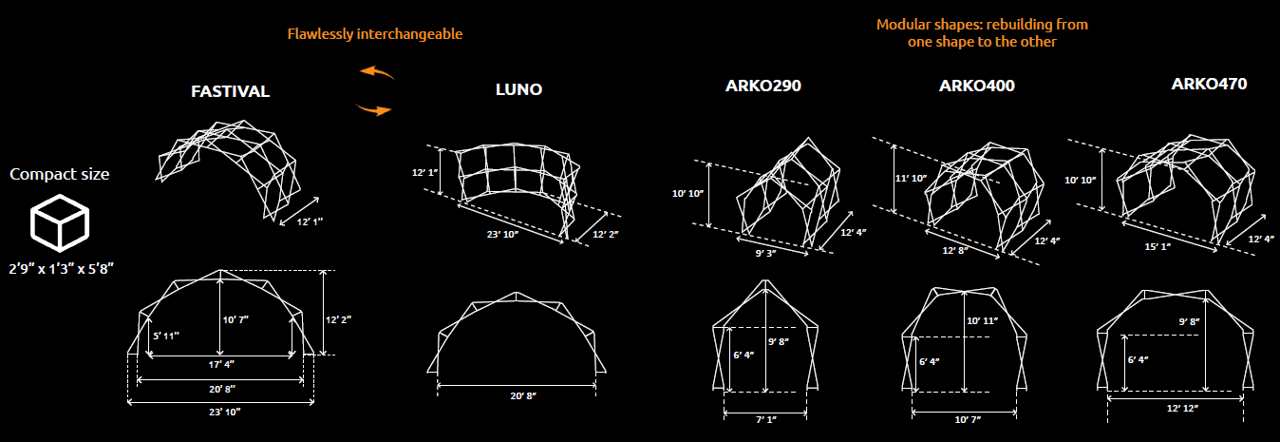

Which sizes and shapes are there available?

Our product range includes a variety of sizes and shapes tailored to meet your specific requirements.

For detailed information, please visit our product page.

Can the size or shape be adjusted to meet the needs of my specific event?

While our products have a fixed span based on the model, you can extend the depth by coupling different models together (by entire or half depth structures).

Additionally, all models can be transformed into a screen (90° rotation) with our Luno package, including wheels and extra foot plates for versatility.

Can I request a custom size or shape?

Absolutely! We call it Konligo Creation :-) Our R&D department specializes in crafting tailor-made shapes to suit your unique project needs. To initiate a custom project, we'll schedule a meeting to discuss your vision in detail. Lead times for custom projects start from 3 months. Contact us to set up a call.

How can I customize a Konligo dome or stage to fit the theme of my event?

The Konligo system boosts incredible versatility, allowing you to customize according to your creative vision. From adding decorative elements and banners to incorporating membranes; your options are limitless. Explore our inspiration gallery here to spark your imagination.

Is a transportation case provided for the structure?

We transport our structures using a cover sleeve made of sturdy polyester. While we can accommodate flight cases for transportation, it significantly increases both weight and cost (approximately €1.500 for the flight case alone, weighing as much as the structure itself). Upon delivery to the customer, we ensure the structures are carefully palletized and completely protected.

What should I do if the cover gets dirty?

For structures with a white PES membrane, dirt accumulates over time. We recommend manual cleaning using soap (no heavy chemicals though) and water to maintain the integrity of the material. Industrial cleaning machines are not recommended as they may damage the PU coating on the membrane. It's important to note that while most dirt can be removed when properly maintained, some may remain. Alternatively, opting for a colored or black membrane reduces visibility of stains. Another option is to choose a PVC membrane, which is easier to clean but pricier and heavier.

Technical specifications

How long does it take to install Konligo stages and domes?

Two people can typically set up or dismantle a Konligo structure within 10 to 15 minutes. However, when factoring in anchoring, adding dead load, and other necessary safety steps, the entire installation process usually takes less than 30 minutes. Note that specific decoration items also add to the installation timing.

Do I need professional help for the installation?

Only two people are required for the setup, but it's important that they are adequately trained to ensure safety and prevent any mishaps. While Konligo structures require a bit more expertise compared to simpler party tents, with proper training, the installation process can be done smoothly and safely.

Which anchoring methods are used?

Konligo structures are anchored with several foot plates, which are secured with ballast, ground pins, or directly screwed into a solid surface. For a 60 km/h wind load, we recommend distributing 450kg of counterweight across the plates, with technical specifications available (page 2) for higher wind conditions.

This is an example of one of the foot plates that comes with the structure.

What is the weight capacity of the stages, and what are the options for rigging?

Depending on wind conditions, our stages can support approximately 40kg at a single point and up to 200kg across the roof. You can also use the adaptors (see next question). Detailed specifications are available in our technical sheets. Don't hesitate to consult our download page for more technical information.

How can I integrate lighting and sound systems with the structures?

We offer adaptors for seamless integration with standard truss clamps, making it easy to use your existing lighting and sound equipment.

Can Konligo structures be installed on uneven ground?

While it's preferable to level the ground, the inherent flexibility of our structures allows for adjustments to accommodate slightly uneven surfaces.

Safety

How do Konligo structures hold up against adverse weather conditions like wind or rain?

Our flagship model, the Fastival, is certified to withstand winds up to 100 km/h (9-10 Beaufort) without a backdrop.

With a closed back, it can endure up to 60 km/h (7 Beaufort). To adapt to higher winds, the backdrop can be easily opened thanks to a zipper system.

Our cover membranes are fully waterproof, ensuring everything and everyone underneath stays dry.

Have you conducted calculations and tests on the structures?

Yes, indeed. As a spin-off from the University of Brussels (VUB)'s Civil & Architectural Engineering departments, our products undergo extensive research, calculations, and testing to ensure they meet stringent safety standards, including Eurocode regulations. We've obtained certifications from reputable organizations such as Vinçotte (Belgium) and CTS (France), and we're currently in the process of securing TUV certification.

Our testing procedures encompass a range of simulations and scenarios. This includes static wind and snow load simulations, where the structure is subjected to forces equivalent to 1.5T. Additionally, we conduct dynamic and fatigue stress tests on joints, involving 40,000 cycles with a tension force of 400kg. Furthermore, real-life wind load scenarios are examined to validate the structural integrity under various conditions.

These rigorous tests ensure that our Konligo structures offer unparalleled safety and reliability.

Is it normal for the structures to move slightly in high winds?

Given its flexible design facilitated by joints and hinges, Konligo structures may experience slight deformations in high winds, unlike rigid stages. However, we meticulously account for these displacements in our calculations, restricting them to within 1% of the structure's span. For instance, in the case of the Fastival model, this translates to a few centimeters.

Compliance & regulations

Are Konligo stages in compliance with safety standards?

Our stages and domes adhere to Eurocode standards for wind and snow load calculations. We have with certifications from Vinçotte (Belgium) and CTS (France), and we're in the process of obtaining TUV certification. The certifications can be downloaded from this page.

Which regulations should be taken into account for concert stages?

Generally, special regulations are minimal for structures lower than 5m in height and smaller than 50m² in area. Nevertheless, we advice to check local guidelines.

Do the membranes/covers have a fire certification?

Yes, our membranes are certified to meet the fire safety standards outlined in DIN 4102-1:1998-05 and EN 13501-1:2018. The certification can be downloaded on this page.

Pricing & investment

What is the total cost of ownership for a Konligo structure?

The primary cost is the purchase price. The maintenance cost is limited. Every 10 to 15 uses we advise you to check the bolt tightness ensuring a smooth installation.

Our R&D department is continuously working on upgrades compatible with all models, ensuring your investment remains up-to-date.

Spare parts are readily available to further extend the lifespan and value of your Konligo structure.

What are the financing options and payment terms?

We do not offer financing and a 50% advance payment is required to secure your order, with the balance due before delivery.

What is the expected lifespan and return on investment for a Konligo structure?

Designed for 250 uses, with proper care, the lifespan of your Konligo structure can be virtually limitless. Occasional part replacements are straightforward, ensuring your structure remains functional and valuable over time.

Ordering & after-sales

How can I place an order?

You can initiate the order process by sending us an email and we'll ensure a thorough follow-up. If we have a distributor in your country, they will handle the process; otherwise, we will assist you directly.

What information do I need to provide when ordering?

Providing us your choice of product would streamline the process.

Can I rent a structure instead of purchasing?

Yes, renting is possible. However, availability may vary depending on whether we have rental partners in your region. Contact us for more information.

What is the production and delivery time?

Typically, our production time is approximately 6 weeks if we have no stock. Delivery duration depends on your location.

What does the warranty cover, and what kind of support can I expect after purchase?

We provide a 5-year warranty on the aluminium frame and a 1-year warranty on coverings. Local support for maintenance and parts replacement is available through our distributor's network.

Do you provide training for technicians on how to set up and maintain Konligo structures?

We offer online videos, manuals, and personal training in Belgium. For international clients, training availability depends on the presence of a local distributor.

Partnerships

Are there opportunities for partnership or collaboration with Konligo?

Konligo is eager to collaborate on expanding our technology and applications. We welcome discussions on partnerships and innovative projects. Plan a meeting with our CEO to discuss the opportunities!

The FAQ related to renting is still under construction.