Innovative Starters Awards 2022

Innovative Starters Awards.

At the beginning of April 2023, the Innovative Starters Awards were presented in Brussels, an initiative of Innoviris Brussels. In addition to Sparklab and Tulipal, Konligo also managed to secure a research fund of no less than €500,000!

But what is the link between Konligo, its foldable domes and stages and a research fund? Automated dome generating software!

Research and innovation in the Brussels region

As a spin-off of the Vrije Universiteit Brussel (VUB), Konligo has never left the Brussels Region. As it turns out, this has been a fruitful decision, since Innoviris annually awards half a million euros to start-ups and scale-ups located in the capital region.

“The mission of Innoviris is to encourage and support research and innovation in the Brussels Region.” Says Stefaan Sonck Thiebaut, General Manager of Innoviris Brussels. “Thanks to an annual financial support of 50 million euros from the Brussels government, we’re able to help companies, start-ups and scale-ups, research centers or collaborative projects. It all fits within a larger strategic framework of the Capital Region: that of economic transition. Our subsidies must serve to help Brussels companies evolve towards a more sustainable economy.

One of our programs is the Innovative Starters Awards, where we annually look for three small innovative companies.” In 2023, Konligo became the proud owner of half a million euros in subsidies. And for that, there are multiple reasons.

The return of Thomas Schoukens

A plan of action was already in place, should we be awarded half a million euros. A project which would be baptized ‘ISA’.

“With the Innoviris funds, we want to drastically change the world of temporary structures (domes and stages) by focusing on custom structures that are modular and whose

components can be reused as much as possible.” says Aushim Koumar, CEO of Konligo. “Imagine building a dome for Tesla that you can convert into a stage for Stromae. Two completely different shapes with the same components. That’s next-level sustainability!”

But we had yet to onboard the necessary talent who we didn’t have to look for, for a long time. Quite the contrary. Thomas Schoukens had already done an internship at Konligo. And for good reason.

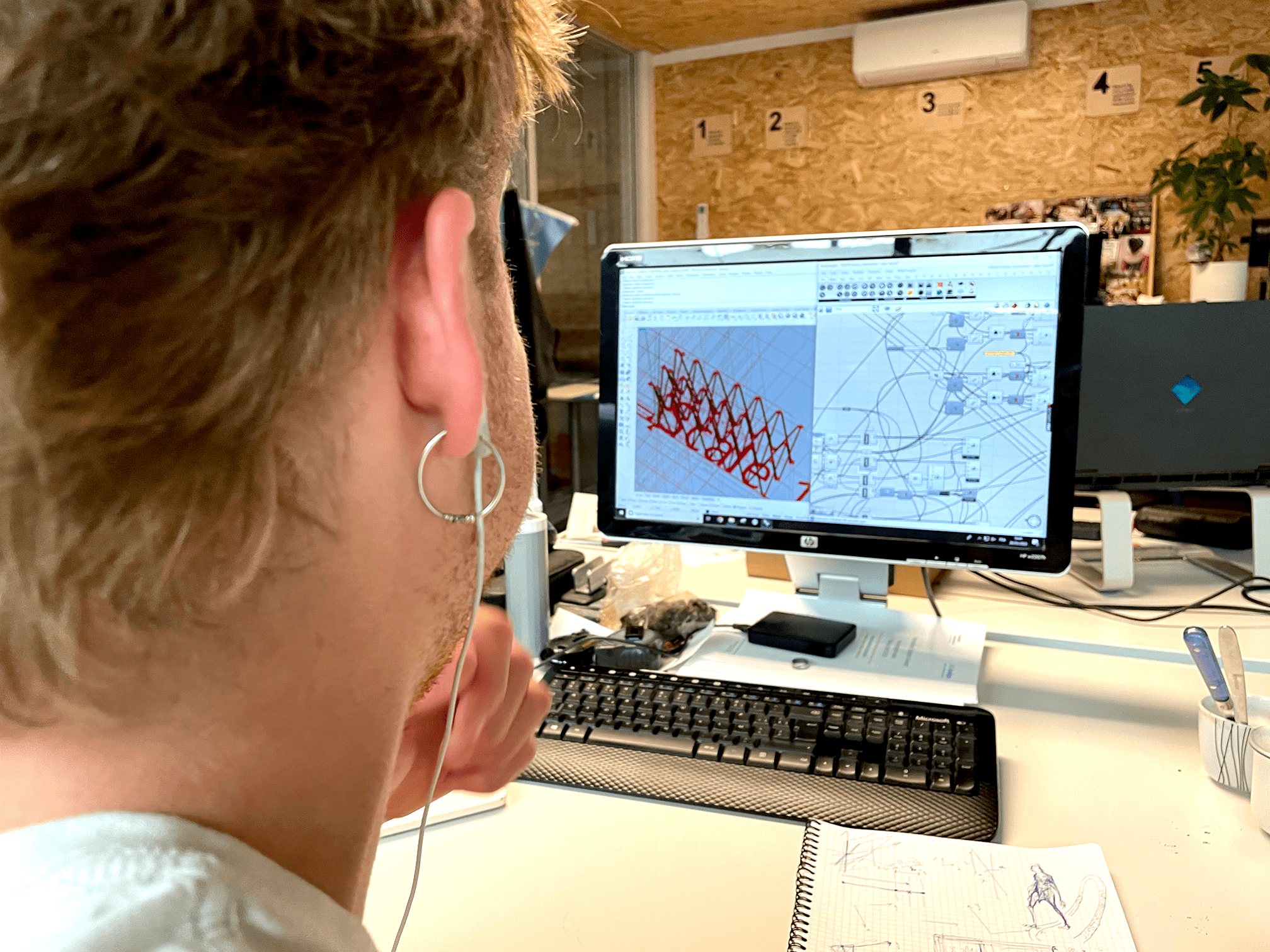

“After his internship in 2020, Thomas very briefly started as a job student on a parametric design project. Ever since then we’ve had his name shortlisted.” says Aushim. “ Thanks to Innoviris’ financial support, we’ve been able to create a job opportunity for a parametric designer. Not long after that, we’ve interviewed Thomas. What followed, is no longer a secret.”

Today, Thomas is a valued team member at the Circularium at Anderlecht, Brussels.

Researching time savings

When Thomas started his architecture studies at the VUB, he heard about Aushim’s doctorate “Deployable structures for disaster relief”. He was immediately intrigued and fascinated with how his field of study could lead

to helping people in emergency situations. “By the time I graduated, Konligo had started as a young startup. I wanted nothing more than to work for them. Alas, they could only offer me an internship. I didn’t miss that opportunity. A couple of years later, thanks to the Innovative Starters Awards, I was able to start at a company whose mission I very much believe in.”

This is how Aushim describes Thomas’ role: “He will develop a software which ensures that engineers spend only one week on a design instead of two months. This will enable us to reduce the production of a custom-made dome or stage from four months to four to six weeks.”

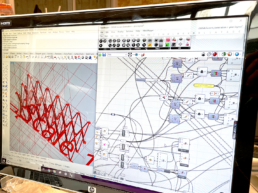

Thomas adds: “Thanks to the funds, there is now room at Konligo to conduct research into new forms and structures. The design of these structures is quite complex: you don’t just come up with a new shape that you immediately develop. My assignment is to set up a generalized working method and to automate it so that custom-made shapes are generated by the computer.

It is very gratifying to be able to play a role in a company whose philosophy is very close to my own moral values and alternative vision. And it must be said that every day I do what I love most: parametric design.”

Much more than a tech company

Information is always more credible when someone external to a company has something to say about that company. Hence we conclude this article with Stefaan Sonck Thiebaut’s wise words: “Konligo is a technology company, based on innovative technology that was developed at the VUB. It responds to a real need and fits perfectly into the theme of ‘economic transition’ as they try to achieve more with fewer raw materials.

We as a region are very grateful to such entrepreneurs because they have the courage to start a new company. That’s not an easy feat. Five years ago there was nothing. And now there is a team, there are products, there are customers, … That’s really impressive.

A product is more than just technology, products and customers. It is also often a social project. I find it impressive that Konligo is very committed to team cohesion and that they work so hard on Konligo’s values. This way they are building a company that has the capacity to realize that scale-up.”

There you go. Now you know we’re not the only ones bragging about our company! All nine of us are very proud to be able to work together on such a beautiful project.

Want to find out more about our innovative research? Discover our weight and wind testing article here.

Ondo, the next wave

Ondo, the next wave.

Challenging yourself. Everyone knows it helps build confidence, increase resilience and even make your life more purposeful. Yet entrepreneuring engineers are often too busy keeping their business afloat, to realize that taking time away from their desks leads to greater things.

The challenge

Baudouin Hubert, one of the co-founders of Konligo, has been challenging Konligo’s team more often than not. In doing market research he met with Arnaud Istas, Head of Business Development at EasyFairs. They wanted to create an inspiration space to be used during the wide range of fairs they organize. The technical requirements were:

- The size did matter. It had to be both big and tall so people could enter the domes and feel inspired;

- We had to avoid rectangular frames;

- It had to be modular and reusable;

- The structure needed to be installed by untrained staff.

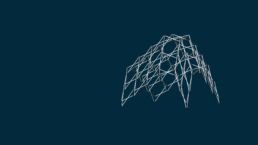

Baudouin convinced our potential customer that we could provide him with a dome that would make a lasting impression on the visitors of the fair EasyFairs was organizing. He then rushed back to the office and challenged Lara (Alegria Mira, another one of the founding members of Konligo) into thinking about how to implement our patented scissor technology in the development of new Konligo domes for EasyFairs. She joined hands with Prof. dr. ir. arch. Niels De Temmerman and from this creative endeavor emerged three different scissor structures: a tree, a more organic form and a shape they randomly baptized ‘The Wave’.

Armed with basic 3D sketches, Baudouin and Lara headed to Ghent to pitch all three ideas. Pretty soon it turned out that the EasyFairs crew wanted ‘The Wave’, since the theme of the upcoming MoOD+Indigo fair that they were organizing in Brussels, was ‘The Next Wave in Textile Trends’.

The clock incessantly continued ticking the time away: only two months and a half were left until the deadline.

Esperanto

It wouldn’t be a Konligo dome if its name wasn’t translated to Esperanto.

You might know by now that the name ‘Konligo’ is in itself derived from the Esperanto word for ‘Connection’: kunligo. Since this word reminded us too much of a French word meaning something completely different, we decided to name it ‘Konligo’. Long story short: ‘The Wave’ became ‘Ondo’. The first tailor-made Konligo dome would soon become a fact!

Every challenge has its sub-challenges

Now came the real work: finding a way to assemble the Ondo dome without using too many different components. With a little help from Niels, Lara reduced the amount of unique components from twenty to five.

Without overthinking it, the team built the Ondo according to Lara’s detailed plans. Building it was one thing, but how would we manage to set it up? Together with Haytam Abdelaoui, an intern doing a master’s thesis on the conceptual validation of a barrel vault scissor structure at the Vrije Universiteit Brussel (VUB), we tried to pull it open from the top using a crane and a ladder to support the crane. Result: a bent ladder.

In came Deus Ex Machina. The tech savvy Baudouin Hubert came up with a tool which would enable us to open the dome from the inside: a front lifter.

Like with all Konligo domes, the Ondo was manually opened to its first opened phase. In came the lifting device which was carefully placed under Ondo's highest peak. Aushim and Haytam turned the front lifters’ handles with great precaution. The suspense was tangible. The Ondo was now completely opened. It was time to retract the front lifter and see if the dome would stay in place. Aushim left Haytam in charge of retracting the lifting device. And behold, a star was born: Ondo didn’t budge. It worked. Lara, who was filming the whole thing, was overjoyed.

Agreed, with its surface of 100m2 and its 6 meters height, the Ondo dome is more massive than the Fastival or the Arko collection and less easy to set up, but it stands out thanks to its unique design.

Next time you think about a specifically shaped dome for your brand activation campaign for instance, don’t think it’s impossible. Just remind yourself that at Konligo, we’re always up for your challenge!